I did try to model some worm gears for acme screws a while ago. They weren't mechanically great. (http://www.thingiverse.com/thing:270309)JustinO wrote: Perhaps there could be tools for designing, machining, and printing worm wheels that work with standard threaded rods and maybe standard acme screws. Print the wheel, buy the worm.

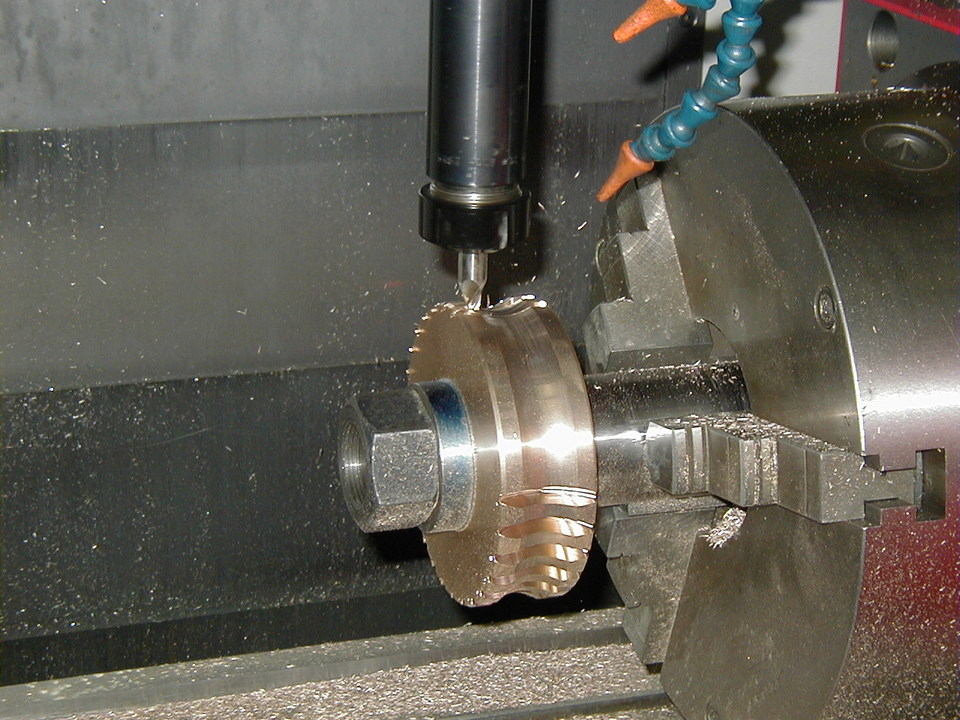

If you know the thread form of the drive screw, and you have a lathe it should be relatively easy to use the same thread form to make a primitive hobbing set up like this: https://www.youtube.com/watch?v=J0o3W4_LRBw